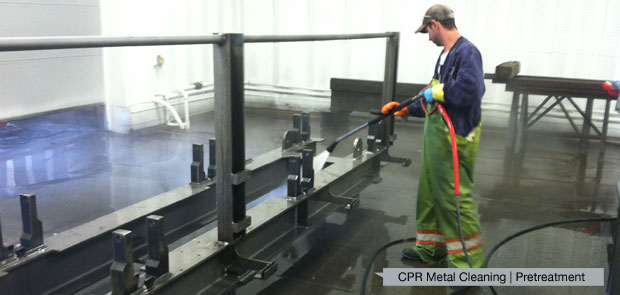

Metal Pretreatment Paint Adhesion And Corrosion Resistance.

The CPR SYSTEM one step clean, pretreat and recycling process improves paint adhesion and corrosion resistance. We offer a 14-day no flash rust guarantee*. Our wash process involves a high-pressure hot water phosphate or zirconium bath. When cleaning, the 180 degree hot water bath immediately evaporates from your metal product leaving behind the phosphate or zirconium solution etched into your metal substrate. The treated product can be further air dried or blown off and taken straight to paint.

- 14-Day no flash rust guarantee*

- Phosphate or zirconium pretreatment

- Increased metal finishing paint adhesion

- Thorough testing and implementation for over 20 years

Our process has been tested by C.A.R.L. Labs on Purdue Universities campus and was found to have superior cleaning power and increased paint adhesion over other pretreatment methods. We increase the quality of your finished product and enhance your customers satisfaction. Our simple, one step process reduces labor, reduces water usage by 95% and reduces phosphate and zirconium consumption by 80%.

Wash bath titration and pH levels are monitored by your personal and adjusted to meet your products specification. This process is simple and training is provided for every installation. We also offer online training demonstrations.

CPR SYSTEMS | CARL Labs Paint Adhesion Testing by