The CPR Metal Pretreatment System...

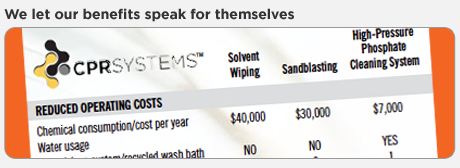

- Reduces water usage by 95%

- Reduces phosphate / zirconium consumption by 80%

- Eradicates waste water discharge

- Eliminates waste water monitoring and reporting

- Eliminates hand wiping, rag and solvent expense

- Improves paint adhesion

- Reduces risk of municipal fines and penalties

- Reduces labor cost

- Increases quality and customer satisfaction

Does your system work with...

Although we designed our phosphate and zirconium wash solutions specifically as non-clogging pretreatment agents we have tested and can suggested other wash / pretreatment solutions provided by your paint representative.

We already have a pressure washer. Can we incorporate it with the CPR SYSTEM to save costs?

Our high pressure Bondtite wash system is designed to perform at certain specifications. If you have a pressure washer and have been pretreating with a phosphate washer previously we can incorporate that washer into our recycling process. We require the specifications of your current washer and sometimes need to adjust pumps or settings to bring the machine to our wash standards.

How much maintenance and monitoring does the CPR SYSTEM require?

The CPR SYSTEM requires daily monitoring of pH and chemical titration levels. This is a simple process that takes less than 15 minutes. Depending on the wash load performed at your facility a weekly or biweekly back washing of filters and other filter maintainance procedures should take place. Depending on usage and dirt load a semiannual system clean-out is preformed to keep the system in top shape.